Product Description

Zinc ethyl silicate paint and all related information

Romolo zinc ethyl silicate paint is a two-component product, these paints also use special resins that provide high temperature resistance. Heat resistance in this category of colors reaches 400 degrees Celsius, but the difference between this type of colors and silicone colors is due to the use of zinc powder, which increases the corrosion resistance of the final coating. Ethyl silicate paints have high density and during the hardening process, they need some humidity in the surrounding environment to complete their chemical reactions. A relative humidity of 60 to 70 percent is usually recommended.

Specifications

Resistant to moisture and water

Resistant to corrosion factors

Resistant to heat and heat up to 400 degrees Celsius

Application

Inner lining of the fireplace wall

Covering all types of pipes and tanks

Covering chemical plant equipment

Inner walls of all types of furnaces, boilers, chimneys

Can be used as coating in refineries, power plants

In general, the main application of these coatings is on surfaces that are in continuous contact

with a high temperature heat source.

Surface preparation:

The desired surface should be cleaned from any pollution such as dust, oil, grease, etc., and the surface should be sandblasted to the standard cleanliness of Sa3-Sa2.5. The required profile for this primer is 25-50 microns.

How to use:

The following devices can be used to apply zinc ethyl silicate paint:

– Airless spray :( pressure 6-7 atmospheres) (nozzle opening 0.457-0.914mm)

How to use

Zinc powder component (B) should be protected from contact with moisture. It is necessary to observe the mixing ratio. Pour the solution component (A) in a suitable container and slowly add zinc powder (B) to it while mixing. Continue stirring until you reach a completely uniform solution and a suitable game. While applying the color, it is necessary to stir the mixture of powder and solution continuously and slowly. It is necessary to observe the speed of hand movement, the distance of the nozzle to the surface of the work piece and the spraying pressure, if the above points are not observed, the work surface will be covered and in more severe cases, the zinc powder will be placed on the work surface in an unstable form and finally separated. Observe the gelling time of the color. At the end, wash all the painting paths with ethyl silicate washing thinner. If paint is applied in a dry environment, it is necessary to spray the surface of the workshop with water to moisten the environment, or atomize the water on the work piece.

How to keep:

The suitable temperature for the storage of the Romolo silicone paint product is 5-40 degrees Celsius, the useful life of this product is 12 months provided that it is kept in the original container, in a covered environment and away from moisture, freezing, extreme heat and direct sunlight.

safety tips:

It is recommended to refrain from inhaling the solvent vapors of this color in closed spaces and use appropriate safety equipment as much as possible and wash with plenty of water in case of contact with skin and eyes, this color is flammable and should be away from heat, sparks and flames. To be distant.

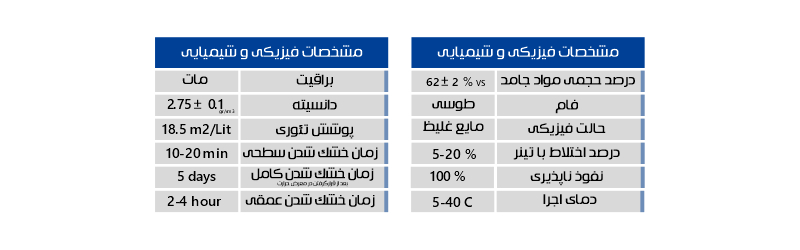

Physical and chemical characteristics:

Romolo company experts are always trying to provide the best requested product according to their needs at the best price after free consultation with their customers.

Romolo Industrial Company operates in the field of selling other industrial paints, including: plastic paints and acrylic paints, types of insulating adhesives and ceramic tile adhesives, and even anti-rusts. For more information, contact us.

| Weight | 20 kg |

|---|

Reviews

There are no reviews yet.