Disadvantages of powdered ceramic tile adhesive

Here, we are trying to gather the most complete source of information about the disadvantages of tile adhesive and powdered ceramic for you. Here, from the beginning, we will examine and compare the products of the manufacturer’s brands, we will answer all the questions in this field, we will examine the formula for making tile and ceramic adhesive products, and then we will examine the unspoken aspects of this industry and a few other things. In this article, you will see tips and steps for the first time that will meet 100% of your needs. By reading this article, you will become an expert in the area of ceramic tile adhesive, which is very effective in choosing a ceramic tile adhesive product wisely.

Welcome to the most complete educational information source for tile adhesive and powder ceramic adhesive. At the end of this article, you will be familiar with 0 to 100 ceramic and tile adhesives and you can easily make a smart purchase and a superior choice among the brands of ceramic and tile adhesives available in the market. It is very important to choose a high-quality and efficient product according to your project and work, it is important to know which product to choose, both in sales and in consumption. For example, when you intend to use powder tile adhesive in your construction project, knowing which product is suitable for your desired space can increase the speed in time and cost. It has happened that in construction projects, due to lack of knowledge about the purchased product, people have applied single-component tile adhesive on the wall, and after a short period of time, the tile has been removed from its place and fell to the ground. Of course, if you are not familiar with these terms, don’t worry; Because in this article, we will describe this industry from zero to one hundred for you so that all people with different knowledge can benefit from its content.

Ask Romolo: Let me share this issue with you from the beginning; In fact, during this article, you will read all the unsaid things from the world of tile and ceramic adhesives, certainly none of the building material manufacturers who sell low-quality products have provided you with this information. They will not be happy, but the Romulo collection considers it its duty to provide this information to the public for free; In fact, you should be aware of the quality of the product you are buying and know whether the product you intend to buy is really the same product that is being introduced to you?!

For the first time in Iran and the Middle East, Romulo Group has been producing ionized building materials under the European license since 2017. This is very involved in increasing the quality of the product and improves the quality of the produced material up to 3 levels. that the consumption volume of your tile and ceramic adhesive product is greatly reduced during a project; That is, if under normal conditions, the lower surface of a facade needs 4 layers of glue and 12 hours of time to dry on the surface, with the ionized product, these figures are reduced to half or even less than half in some weather conditions, which is the main reason. Reducing the price of the consumed product, reducing the weight of the building and reducing the cost of labor.

What are the disadvantages of powder ceramic tile adhesive?!

Tile and ceramic adhesives are another new achievement in the construction industry, which are used instead of mortars in many small and large projects today. It is much easier to use and it is a type of ready-made mortar for gluing ceramic tiles on different surfaces. Ceramic and tile adhesives are offered in different models by many manufacturers, each of which has different price, quality and ability to stick different ceramic tiles on different surfaces depending on the type of model.

With the growth and advancement of technology in recent years, various industries underwent a drastic transformation. For example, for the ease, security and peace of human beings during road traffic, the technology of self-driving smart cars was launched on the market, and there are several examples that show the evolution of industries thanks to the advancement of technology in the world. The construction industry and construction structures have not been spared from this growth and are undergoing huge changes in the world day by day. Currently, thanks to mechanical structures, access to the highest and farthest points of the towers has become very easy for maintenance, and there is no need to destroy the wall for a burst pipe under the isogam anymore due to the existence of insulation adhesives. Because the base of insulation glue is the same water, which can be easily cleaned with an acid solution and can be easily applied again after the repair of the liquid insulation pipe. Another sector of the construction industry that has undergone a lot of transformation and growth is the sector related to tile and ceramic adhesive.

Disadvantages of tile adhesives and powdered ceramics:

The most basic discussion that we have to address in this article is the types of tile and ceramic adhesives. You may not know, but if at one stage you intend to work with marble on the wall of your building and at another stage you want to work with mosaic on the floor, you need two adhesives with different characteristics. This also applies to restoration, reconstruction and renovation.

- Powder tile adhesive

- Paste tile glue

In general, tile and ceramic adhesives are divided into powder and paste categories. It is very simple to distinguish the use of these two, just consider one thing: are you renovating and repairing a part of the structure or are you planning to renovate and build a building structure from the ground up?!

Paste tile glue is actually used on the wall and old tiles during renovation; You can use this glue on glass and different types of surfaces; So, if you plan to renovate, you must use ceramic tile glue. In the continuation of this article, we will discuss the method of working with paste tile adhesive on different surfaces; As for the powder tile adhesive, which is widely used in this industry, it is one of the most widely used products in the construction industry. Powdered tile adhesive is used only for renovation purposes; That is, if you are planning to build a building structure from the ground up, you must use tile and ceramic powder glue. Powdered tile adhesive has several different models, which are divided into 2 to several models according to the manufacturer’s formulation.

Powder tile glue:

- Single-component powder ceramic tile adhesive

- Two-component powder ceramic tile adhesive

The main difference of powder tile adhesive is summarized in the above two cases. In fact, the main policy of this division is based on the fact that you spend less to buy the right product according to your needs. Both of these models are actually the same powder tile adhesives with differences in their quality. Some companies have removed ingredients and additives from two-component powder adhesives in their formulation in order to reduce costs and become single-component powder adhesives.

Single component powder tile adhesive:

As mentioned above, this type of powdered ceramic and tile adhesive has a lower quality than the two-component model of this adhesive; Of course, we should also mention that this issue has nothing to do with the quality of the ceramic and tile adhesive material, and it only has a different application in a specific space. For example, if you need to pave the parking lot; Well, of course, buying a high-adhesion powder tile adhesive that is suitable for working with slab stone in high-rise facades is a bit unreasonable; Because you don’t need to spend money and buy such a high-use adhesive, and a less absorbent adhesive is also a good answer for your work. As a result, companies and companies producing tile adhesives thought of dividing work adhesives into two categories, one-component and two-component, with different uses, which causes the purchase price for the user to increase in proportion to the difficulty and the need of the project. And the user is not required to buy a high-priced glue.

Single-component powder tile adhesives are used only on the ground surface for gluing tiles and light mosaics, which are mostly used for facades. Please note that only this type of powder adhesive is allowed on the floor. The adhesion and absorption ability of this glue is such that it cannot be used on the wall and vertical surface, and it can only be used well in gluing tiles and light mosaics on the floor. Of course, keep in mind that the quality of these types of products varies greatly according to the formulation used in the production of glue by the manufacturing company; For example, a two-component adhesive produced by one company may be weaker than a one-component adhesive from another company. We will examine this case well in the following.

Two-component powder tile glue:

Two-component powder tile adhesives are actually the same as the single-component version, which have been increased in quality by adding some special materials and compounds (which we will discuss further). The ability of these types of adhesives to stick ceramic tiles on the floor and wall is very high. In fact, you can use this product both on the floor and on the facade and easily stick all kinds of slab stones, porcelain ceramics, etc. Of course, keep in mind that here we mean a pure powder tile adhesive with good quality; In general, two-component powder glue is suitable for gluing porcelain slabs and ceramics. The price of this model of tile powder coating is much higher than the single-component version, and this is due to the quality, absorption and ability to stick and maintain this model compared to the single-component version.

How to use paste tile adhesive:

Paste tile adhesive is actually a type of ready-to-use paste mortar; As it was already mentioned, the paste tile adhesive sticks on tiles, ceramics, glass, etc. to restore and restore surfaces. The quality of the paste tile adhesive product depends on the formulation of the adhesive structure; Of course, if you want to be sure of the quality of the purchased product, the paste tile adhesive should be elastic, preferably white. The dry time of the product is another item that shows the strength and quality of the paste adhesive product; In this way, the shorter the drying time of the product, the stronger its adhesion and absorption.

Now let’s look at how to work with paste tile adhesive on different surfaces; First, clean the surface below the work from any dirt and grease and make a few lines on the desired surface with an ax or a grinding stone. Then apply paste glue with a combed spatula to a maximum area of one square meter and a thickness of 3-4 mm on the wall and stick the wet tile on the surface within 3-5 minutes. The tiles installed on the wall will reach their final strength after 12-24 hours, and after this time, you can start the grouting, which can be used two days after grouting the desired surface. The suitable temperature for installing paste tile adhesive is 5-25 degrees Celsius.

The very important point of this issue is that the amount of adhesive paste depends on the type of work and how the ridges are on the back of the ceramic tile and is usually equal to 3 to 4 kg per square meter.

How to use powder tile adhesive:

We mentioned above that you can use powder tile adhesive to stick tiles, ceramics, mosaics, etc. on surfaces. Of course, you should keep in mind that you are only allowed to use powder tile adhesive when you want to build a structure from the ground up and do not intend to repair or rebuild it. The quality of powder tile adhesive is slightly different from the quality of paste adhesive product. Of course, I have to tell you that we have included a section to determine the quality of ceramic and tile adhesives below, and here we will only discuss some key points to determine the quality of the product. First, let me express one of my experiences; In my opinion, this simple method is very practical and is responsible for detecting the quality of your product up to 90% of the time.

First, see the packaging, the design on the cover and the appearance of the product; Generally, the original and high-quality product has a very beautiful and elegant appearance; But if you still want to be sure of your purchase, you should first check the drying time of the product; Being waterproof and a few other things that we will discuss in the following are the reasons for the high quality of the powder tile adhesive product.

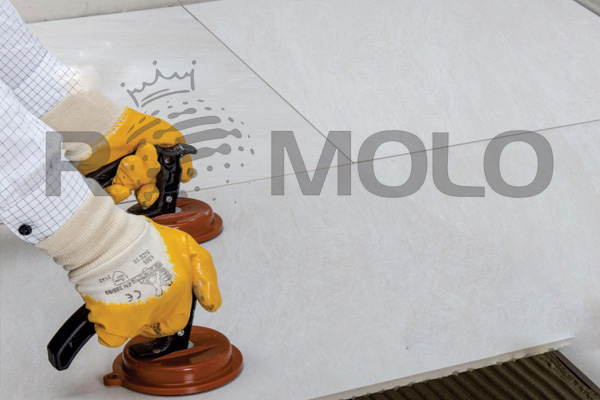

The method of applying the powder ceramic and tile adhesive product is that at first, the desired surface should be cleaned from any pollution and if there are tiles and cement, it should be axed, and then every 4 kilos of adhesive should be mixed with one liter of water. and mix thoroughly. With a grooved spatula, apply enough mortar on the place and back of the tile with one hand and install it on the desired surface. The amount of consumption is generally 4-5 kg per square meter. The suitable ambient temperature for using white porcelain powder glue is 5-35 degrees Celsius.

Ceramic tile adhesive formulation:

If you are reading this article, it is not out of the three modes; You may be a store that intends to add a new brand of tile and ceramic adhesive products to your store; Either you have visited this source to buy ceramic tile adhesive for your desired project, so that you can make a smart choice in your purchase, or you intend to produce a ceramic tile adhesive product. In any case, this section can help you a lot because, in any case, discovering the formulation and contents of the tile adhesive product can open your view of this product so that you can examine the product with specialized knowledge.

Depending on the brand that produces the tile and ceramic adhesive product, its internal contents may change, of course, we check all of them; But the part of the formulation that is fixed and unchangeable is the part related to its base.

Another article under the title of disadvantages of tile and ceramic adhesive is at your service, dear friends and regular companions of Romulo. We always try to believe that we can collect the most complete sources of information for you dear ones, so that you can act in the smartest possible way when buying the desired product. Here we are going to check all the advantages and disadvantages of using ceramic tile adhesive and finally have detailed general information about this widely used product. As you are aware, currently, many brands in the Iranian market are producing tile and ceramic adhesive, and this causes confusion for users when purchasing the product; Here, we introduce all the brands of tile and ceramic adhesive to you, and then we compare them in terms of price and product quality.

Be careful that all our statements in this article, like other articles, are correct and written based on complete honesty. We are very happy that we have been able to take a small step in the direction of informing people in the construction material industry and to gain your trust and opinion. Join Romulo’s big family right now and benefit from Romulo’s content, articles and products with a special discount.

Welcome to the most complete educational reference for tile and ceramic glue. In this article, we are going to examine all possible disadvantages and problems of using powder tile adhesive; Note that here we always consider the criteria based on honesty and we will announce everything that is really to you dear and constant companions of Romulo. At the end of this article, you will know which product from which brand is useful for you and you can make the best and smartest choice in buying your powder ceramic and tile adhesive product. In this section, we will only review the powder glue products available in the market; To view the rest of the articles, you can refer to the articles page or refer to the article you want at the end of this article. It is very important to choose a high-quality and efficient product according to your project; Knowing which product to choose will greatly increase your work and save money and time.

For example, when you intend to use tile adhesive and ceramic powder in your construction project, knowing which product is suitable for your desired space can increase the speed in time and cost. Romolo collection has always tried to believe this to be able to introduce the best choice to you dear ones and regular users of this collection; Unfortunately, many activists in this field are only looking for the sale of their goods and do not pay attention to the needs of the users. Here, we established the standard based on honesty and always sought to provide the highest quality to you dear ones. Stay with us in the rest of this article.

Ask Romolo: Let me share this issue with you from the beginning; During this article, you will read all the unsaid and corners of the world of normal and ionized ceramic tile adhesive; Here, we will tell you the reasons for not using some brands, and on the other hand, we will also introduce you to reliable and high-quality brands; Of course, none of those manufacturers and operators in the building material area who sell low-quality products will not be happy that we have provided you with this information, but Romulo Group has considered it its duty to provide you with this information without any eyes. public place; In fact, you should be aware of the quality of the product you are buying and know whether the product you intend to buy is really the same product that is being introduced to you?!

For the first time in Iran and the Middle East, Romulo Group has been producing ionized building materials under the European license since 2017. This is very involved in increasing the quality of the product and improves the quality of the produced material up to 3 levels. that the consumption volume of your tile and ceramic adhesive product is greatly reduced during a project; That is, if under normal conditions, the lower surface of a facade needs 4 layers of glue and 12 hours of time to dry on the surface, with the ionized product, these figures are reduced to half or even less than half in some weather conditions, which is the main reason. Reducing the price of the consumed product, reducing the weight of the building and reducing the cost of labor.

Powdered ceramic tile adhesive

Tile adhesive and ceramic powder are one of the biggest and most important achievements in the history of the construction industry. This unique product has replaced its previous version, the traditional mortar. Currently, traditional mortars are no longer used in construction projects in the world because with the advancement and development of the tile and ceramic industry, traditional mortars are no longer able to maintain and stick them on different surfaces; Therefore, the tile adhesive product has completely replaced the traditional mortar in the world. Now, here we are going to examine this product in more detail first of all; Let’s know its history and find out all the details of this product. Stay with us.

The growth and development of technology in recent decades has been very high. This growth has been done in almost all basins and has reached its peak in some. Our own country, Iran; In all fields and other job sectors, work cannot be carried out without technology. In recent years, communication technology and information technology have worked in such a way that it is no longer possible to spend day and night without technology. This growth has also occurred in the construction industry and building materials.

If you were planning to build a building structure in the past 20 years, you should have used traditional mortar to connect the tiles and ceramics to the wall and floor surfaces. In fact, the people who are called master builders used a mixture of cement, water and broken sand to create a sticky mixture that was not based on any specific criteria or size. The more experienced the person, the greater the stickiness of the mortar. With the growth and progress of the tile and ceramic industry, ceramics and stones with larger dimensions and weight were produced. Other traditional mortars were not able to stick slab stones and porcelain ceramics on the wall and floor.

Over time; The use and exploitation of more modern stones and ceramics, which had higher dimensions and weight, flourished and reached its peak. Meanwhile, two types of powder and paste types of tile and ceramic adhesives were born. These products had higher adhesion, more resistance and the ability to easily store stones and ceramics with higher dimensions and weight. The price of these products was much higher than the traditional mortar, but it provided the consumer with 100 times more quality and adhesion.

Types of powder ceramic and tile glue:

Tile adhesive and ceramic powder are divided into two categories in the world. This classification has nothing to do with the manufacturer of the product, or it is considered a universal parameter for powder ceramic glue, which is the same in all parts of the world. These two categories are as follows:

- Single-component powder ceramic tile adhesive

- Two-component powder ceramic tile adhesive

But the question that arises is why they divide a product into two categories?!

It might seem a little confusing at first, but don’t worry; You are going to get all the information you need from this article once and for all.

The main reason for this classification of powder glue is actually related to the type of product use. That is, if you intend to use porcelain ceramic on the floor, you must use a special type of glue; On the other hand, if you intend to use mosaic on the floor, you should use another type of powder glue. Of course, I should include this issue here that the use of powder tile adhesive is used only as a construction of a structure, not its reconstruction. If this item has confused you or you want to be sure whether you should use powder glue or paste glue, we suggest you visit Romulo’s article. In this article, we have opened the whole tile adhesive and we have dedicated a part to the use of powder and paste adhesive. You will definitely get your answer by reading this article.

Let’s go back to our main discussion; We have two types of powder glue in the market, we are going to check these types of powder glue.

Single component powder ceramic tile adhesive:

The one-component ceramic and tile adhesive product actually, as its name suggests, has the lowest degree of adhesive strength and quality compared to its two-component sample. Of course, this does not mean that a single-component adhesive is considered a low-quality product; no

This product does not need higher quality just because of its application and type of use; As a result, in order to make the purchase price suitable for consumers, users can use the single-component type with a little lower adhesion. The remarkable thing about single-component powder glue is its application; You are only allowed to use this glue on the floor; In fact, this product is not able to stick ceramics and tiles to the wall and facade of the building, and it only has the ability to stick to the floor. Of course, you should also keep in mind that you should not use large and heavy tiles and ceramics when using single component glue. You can work with all kinds of mosaics and light weight tiles on the floor with this product.

Keep in mind that due to the adhesive strength of the single-component product, it is better if you plan to use it in an environment near water (for example, a swimming pool, jacuzzi, etc.) Use inside the glue; Of course, it is better not to use single-component glue in environments that are in direct proximity to water.

Two-component powder tile glue:

The two-component powder tile adhesive product is actually a stronger and higher quality version. With this product, you can install all the tiles and ceramics with different dimensions and sizes wherever you want. You can use porcelain ceramics on exterior wall surfaces and… Stick the building and don’t worry about its absorption and adhesion. Of course, in relation to the adhesion of the product, part of it is related to the gluing method, which in the following we will fully explain to you the correct and standard method of using tile adhesive. The ability of these types of adhesives to stick ceramic tiles on the floor and wall is very high. In fact, you can use this product both on the floor and on the facade and easily stick all kinds of slab stones, porcelain ceramics, etc. Of course, keep in mind that here we mean a pure powder tile adhesive with good quality; In general, two-component powder glue is suitable for gluing porcelain slabs and ceramics. The price of this model of powder tile adhesive is much higher than the single-component version, and this is due to the quality, absorption, and ability to stick and maintain this model compared to the single-component version.

about us:

Romolo has several years of experience in the production of concrete adhesive, insulating adhesive and various silicone paints such as white silicone paint, black silicone paint, and our other best-selling products are slab powder tile adhesive and porcelain powder tile adhesive.

In addition to that, you can refer to the relevant links to view the products of sealing glue, various types of strapping plus powder or sealing paste.